- HOME

- Product

- Piping Materials

Product

Piping Materials

FITTING

WROUGHT STEEL BUTTWELD PIPE FITTING

90° ELBOW

90° ELBOW

45° ELBOW

45° ELBOW

STRAIGHT TEE

STRAIGHT TEE

CONCENTRIC REDUCER

CONCENTRIC REDUCER

CAP

CAP

| ITEM | SIZE |

|---|---|

| ELBOW [45°/90°/180°] | 1/2” - 94” |

| TEE [STRAIGHT/REDUCING] | 1/2” - 84” |

| REDUCER [CONCENTRIC/ECCENTRIC] | 1/2” - 48” |

| CAP | 1/2” - 132” |

FORGED STEEL FITTING

ELBOW

ELBOW

TEE

TEE

CAP[HEX/ROUD]

CAP[HEX/ROUD]

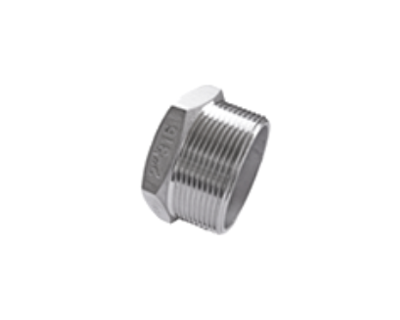

PLUG

PLUG

[HEX/ROUND/SQUARE] UNION

UNION

COUPLING [FULL/HALF]

COUPLING [FULL/HALF]

SOCKOLET

SOCKOLET

THREADOLET

THREADOLET

NIPPLEOLET

NIPPLEOLET

SWAGE NIPPLE

SWAGE NIPPLE

Table 1. Correlation of Fittings Class with Schedule Number or Wall Designation of Pipe for Calculation of Ratings.

| Pressure class Designation of fitting | Type of Fitting | Pipe Used for Rating Basic | |

|---|---|---|---|

| Schedule No. | Wall Designation | ||

| 2000 lb | Threaded | 80 | X-S |

| 3000 lb | Threaded | 160 | - |

| 6000 lb | Threaded | - | XX-S |

| 3000 lb | Socket-Welding | 80 | X-S |

| 6000 lb | Socket-Welding | 160 | - |

| 9000 lb | Socket-Welding | - | XX-S |

This table is not intended to restrict the use of pipe of thinner or thicker Wall with fittings. Pipe actually used may be thinner or thicker in nominal Wall than that shown in Table 1. When thinner pipe is used its strength may Govern the rating. When thicker pipe is used, the strength of the fitting governs the rating.

Table 2. Nominal Wall Thickness of Schedule 160 and Double Extra Strong Pipe

| NPS | Schedule 160 | XX-S | ||

|---|---|---|---|---|

| Inch | mm | Inch | mm | |

| 1/8 | 0.124 | 3.15 | 0.190 | 4.83 |

| 1/4 | 0.145 | 3.68 | 0.230 | 6.05 |

| 3/8 | 0.158 | 4.01 | 0.252 | 6.40 |

MATERIAL

| Ferrous Material | |||||

|---|---|---|---|---|---|

| Material Classification | Comparison as Nations | ||||

| Large | Middle | Small | ASTM (U.S.A.) | ||

| Disignation | Identification | ||||

| Ferrous

(Base Material: Fe) | Carbon Steel | Ambient and Higher

Temperature Service |

A234 | WPB | |

| WPC | |||||

| Low Temperature Service |

A420 | WPL3 | |||

| WPL6 | |||||

| WPL9 | |||||

| Alloy Steel (Cr≥1%) | Low Alloy (1%≤Cr≤9%) | A234 | WP1 | ||

| WP12 | |||||

| WP11 | |||||

| WP22 | |||||

| WP5 | |||||

| WP23 | |||||

| WP9 | |||||

| WP91 | |||||

| WP92 | |||||

| High Alloy (Cr≥12%)

Stainless Steel |

Martensitic Stainless Steel | A815 | WP410 | ||

| Ferritic Stainless Steel | WP430 | ||||

| Austenitic

Stainless Steel |

A403 | WP304/L | |||

| WP316/L | |||||

| WP317/L | |||||

| WP321/H | |||||

| WP347/H | |||||

| Super Austenitic

Stainless Steel |

A403 | S31254 | |||

| 904L | |||||

| Ferritic / Austenitic

(Duplex / Super Duplex) |

A815 | S31803 | |||

| S32750 | |||||

| S32760 | |||||

*Applicable Code / Standard : ASTM Part A, Latest Edition.

Non Registered materials on ASTM Latest Edition

| Non-Ferrous Material Comparison | ||

|---|---|---|

| Material Classification | Trade Mark | UNS No. |

| Non-Ferrous

(Base Material : Ni) |

Inconel 600 | N06600 |

| Inconel 690 | N06690 | |

| Inconel 800HL/800HT | N08810 / N08811 | |

| Inconel 625 | N06625 | |

| Inconel 825 | N08825 | |

| Hastelloy B2 | N10665 | |

| Hastelloy C276 | N10276 | |

| Hastelloy C22 | N06022 | |

| Incoloy 020 | N08020 | |

| Monel 400 | N04400 | |

| Monel K500 | N05500 | |

| Non-Ferrous

(Base Material : Cu) |

Cu-Ni 70/30 | C71500 |

| Cu-Ni 90/10 | C70600 | |

*Applicable Code / Standard : ASTM Part B, Latest Edition

SPECIFICATION

KS: KOREAN INDUSTRIAL STANDARDS

| KS B 1522 | Steel Butt Welding Pipe Fittings for Ordinary use and Fuel Gas. |

|---|---|

| KS B 1541 | Steel Butt Welding Pipe Fittings. |

| KS B 1542 | Steel Socket Welding Pipe Fittings. |

| KS B 1543 | Steel Plate Butt Welding Pipe Fittings. |

JIS: JAPANESE INDUSTRIAL STANDARDS

| JIS B 2311 | Steel Butt Welding Pipe Fittings for Ordinary use. |

|---|---|

| JIS B 2312 | Steel Butt Welding Pipe Fittings. |

| JIS B 2313 | Steel Plate-Butt Welding Pipe Fittings. |

| JIS B 2316 | Steel Socket Welding Pipe Fittings. |

ASTM: AMERICAN SOCIETY FOR TESTING AND MATERIALS

| ASTM A 105 | Carbon Steel Forgings for Piping Applications. |

|---|---|

| ASTM A 182 | Forged or Rolled Alloy-Steel Pipe Flanges, Forged Fittings and Valves and Parts for High-Temperature Service |

| ASTM A 234 | Piping Fittings of Wrought Carbon Steel and Alloy Steel for Moderate and High Temperature Service. |

| ASTM A 350 | Carbon and Low-Alloy Steel Forgings, Requiring Notch Toughness Testing for Piping Components. |

| ASTM A 403 | Wrought Austenitic Stainless Steel Piping Fittings. |

| ASTM A 420 | Piping Fittings of Wrought Carbon Steel and Alloy Steel for Low Temperature Service. |

| ASTM A 694 | Carbon and Alloy steel Forging for Pipe Flanges, Fittings, Valves, and Parts for High-Pressure Transmission Service. |

| ASTM A 815 | Wrought Ferritic, Ferrite / Austenitic, and Martensitic Stainless steel Piping Fittings. |

| ASTM A 860 | Wrought High-Strength Low-Alloy steel Butt Welding Fittings. |

| ASTM A 366 | Factory-Made Wrought Nickel and Nickel Alloy Fittings. |

MSS: MANUFACTURERS STANDARDIZATION SOCIETY OF THE VALVE AND FITTINGS INDUSTRY

| MSS SP-25 | Standard Marking System for Valves, Fittings, Flanges and Unions. |

|---|---|

| MSS SP-43 | Wrought Stainless Steel Butt Welding Fittings. |

| MSS SP-44 | Standard for Steel Pipe Line Flanges. |

| MSS SP-75 | Specification for High Test Wrought Butt Welding Fittings. |

| MSS SP-79 | Socket Welding Reducer Inserts. |

| MSS SP-83 | Carbon Steel Pipe Unions Socket welding and Threaded. |

| MSS SP-87 | Factory-Made Butt Welding Fittings for Class 1 Nuclear Piping Applications. |

| MSS SP-95 | Swage(d) Nipples and Bull Plugs. |

| MSS SP-97 | Integrally Reinforced Forged Branch Outlet Fittings-socket Welding, Threaded and Butt Welding Ends. |

ASME: AMERICAN SOCIETY OF MECHANICAL ENGINEERS

| ASME B 16.5 | Pipe Flanges and Flanged Fittings. |

|---|---|

| ASME B 16.9 | Factory Made Wrought Steel Butt-Welding Fittings. |

| ASME B 16.11 | Forged Steel Fittings, Socket-Welding and Threaded. |

| ASME B 16.25 | Butt-Welding Ends. |

| ASME B 36.10 | Welded and Seamless Wrought Steel Pipe. |

| ASME B 36.19 | Stainless Steel Pipe. |

| ASME B 31.1 | Power piping. |

| ASME B 31.3 | Process piping. |

| ASME SECTION II | Materials. |

| ASME SECTION III | Rules for Construction if Nuclear Facility Components. |

| ASME SECTION V | Nondestructive Examination. |

| ASME SECTION VIII | Rules for Construction of Pressure Vessels. |

| ASME SECTION IX | Welding and Brazing Qualifications. |

API: AMERICAN PETROLEUM INSTITUTE

| API 5L | Line Pipe. |

|---|

-

Location 28, Gadal 2-ro 55beon-gil, Gangseo-gu, Busan, 46729, Korea

-

TEL +82-51-710-1551

-

E-mail darinsteel@naver.com

-

FAX +82-51-710-1552